Welcome to Dalian Daxin Machinery Co., Ltd.

Toggle Navigation

The C series conventional lathes can turn the outer circle, inner hole and face of the parts. It can drill holes, ream holes and pull oil grooves. Various metric, imperial, module and diametral pitch threads can be processed. If users place special orders, circular pitch threads can also be processed. Materials such as steel, cast iron, non-ferrous metals and non-metals can be machined. This lathe is particularly applicable to processing workshops with small batch production and mechanical repair workshops, etc. The dimensional accuracy of the machined parts can reach IT7 grade, and the surface roughness can reach 1.6 grade.

|

Main technical specification |

Unit |

C6140B |

C6150B |

C6166B |

C6150C |

C6166C |

||||||||

|

Specification |

||||||||||||||

|

Max.swing diameter over bed |

mm |

φ400 |

φ500 |

φ660 |

φ500 |

φ660 |

||||||||

|

Max.swing diameter over cross slide |

mm |

φ230 |

φ290 |

φ440 |

φ290 |

φ440 |

||||||||

|

Max.swing diameter in gap |

mm |

φ700 |

φ760 |

φ870 |

φ760 |

φ870 |

||||||||

|

Length in gap |

mm |

280 |

||||||||||||

|

Max.workpiece length |

mm |

750/1000/1500/2000/3000 |

||||||||||||

|

Max.cutting length |

mm |

700/950/1450/1950/2950 |

||||||||||||

|

Spindle |

||||||||||||||

|

Spindle nose |

|

D8/C8 (The C-series machines are only for D8.) |

||||||||||||

|

Spindle bore diameter

|

mm |

φ82 |

φ105 |

|||||||||||

|

Chuck size |

mm |

φ250 | φ250 | φ315 | φ315 | |||||||||

|

Spindle bore taper |

|

90 mm / 1:20 |

110 mm / 1:20 |

|||||||||||

|

Max.spindle torque |

Nm |

1000 |

||||||||||||

|

Spindle speed ranges |

rpm |

26 - 2000 |

26 - 1700 |

|||||||||||

|

Spindle centre height |

mm |

220 |

250 |

325 |

250 |

325 |

||||||||

|

Spindle motor power |

kw |

7.5 (10 HP) |

||||||||||||

|

Tailstock |

||||||||||||||

|

Tailstock quill diameter |

mm |

φ75 |

||||||||||||

|

Tailstock quill travel |

mm |

150 |

||||||||||||

|

Tailstock quill taper |

|

No.5MT |

||||||||||||

|

Feeds&Threads(metric screw*inch screw) |

||||||||||||||

|

Longitudinal feed |

|

0.044-1.48mm/rev(45kinds) |

||||||||||||

|

Cross feed |

|

0.022-0.74mm/rev(45kinds) |

||||||||||||

|

Metric threads |

mm |

0.35 - 80(73kinds(53kinds British imperial machine tools)) |

||||||||||||

|

Modular threads |

mm |

0.2 - 40 MOD(45kinds(66kinds British imperial machine tools)) |

||||||||||||

|

Inch threads |

TPI |

7 / 16 - 80(47kinds) |

||||||||||||

|

Diametral pitch threads |

DP |

7/8 - 160(47kinds) |

||||||||||||

|

Tool post |

||||||||||||||

|

Max.tool shank size |

mm |

25x25 |

||||||||||||

|

Top slide travel |

mm |

150 |

||||||||||||

|

Machine dimensions |

Machine length |

mm |

2360/2610/3110/3610/4610 |

|||||||||||

|

Machine width |

mm |

1226 |

||||||||||||

|

Machine height |

mm |

1390 |

1440 |

1520 |

1440 |

1520 |

||||||||

|

Machine weight |

Distance between centers |

750mm |

kg |

2020 |

2070 |

2120 |

2070 |

2120 |

||||||

|

1000mm |

kg |

2070 |

2120 |

2170 |

2120 |

2170 |

||||||||

|

1500mm |

kg |

2120 |

2170 |

2220 |

2170 |

2220 |

||||||||

|

2000mm |

kg |

2230 |

2280 |

2330 |

2280 |

2330 |

||||||||

|

3000mm |

kg |

3010 |

3060 |

3150 |

3060 |

3150 |

||||||||

● 3-Jaw chuck

● Tool post guard

● Chuck guard

● 4-way tool post

● Steady rest(≥1500mm-Standard <1500mm-Option)

● Follow rest(≥1500mm-Standard <1500mm-Option)

● Standard toolkit

● 4-Jaw chuck

● 11kw spindle motor

● Rear splash guard

● Center of tailstock

● Face plate

● Thread dial

● Taper-turning attachment

●DRO

●Anchor bolts

●Spindle center and center sleeve

●Adjustable pads

Persist with the policy of continual product improvement, we reserve the right to amend the specifications in this catalog without prior notice.

|

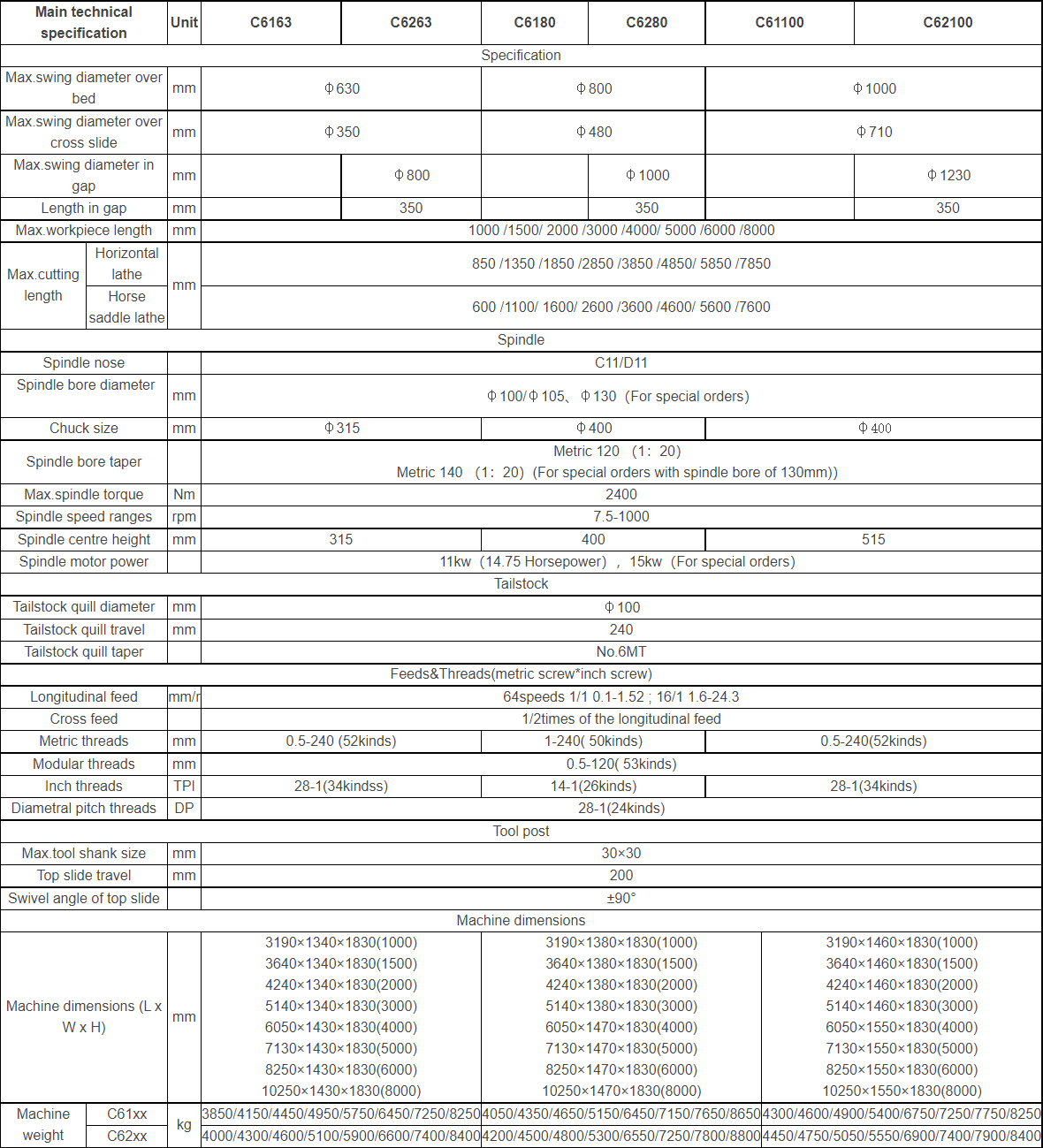

Main technical specification |

Unit |

C6163 |

C6263 |

C6180 |

C6280 |

C61100 |

C62100 |

|||

|

Specification |

||||||||||

|

Max.swing diameter over bed |

mm |

φ630 |

φ800 |

φ1000 |

||||||

|

Max.swing diameter over cross slide |

mm |

φ350 |

φ480 |

φ710 |

||||||

|

Max.swing diameter in gap |

mm |

|

φ800 |

φ1000 |

|

φ1230 |

||||

|

Length in gap |

mm |

350 |

|

350 |

|

350 |

||||

|

Max.workpiece length |

mm |

1000 /1500/ 2000 /3000 /4000/ 5000 /6000 /8000 |

||||||||

|

Max.cutting length |

Horizontal lathe |

mm |

850 /1350 /1850 /2850 /3850 /4850/ 5850 /7850 |

|||||||

|

Horse saddle lathe |

600 /1100/ 1600/ 2600 /3600 /4600/ 5600 /7600 |

|||||||||

|

Spindle |

||||||||||

|

Spindle nose |

C11/D11 |

|||||||||

|

Spindle bore diameter

|

mm |

φ100/φ105、φ130(For special orders) |

||||||||

|

Chuck size |

mm |

φ315 |

φ400 |

φ400 |

||||||

|

Spindle bore taper |

Metric 120 (1:20) |

|||||||||

|

Max.spindle torque |

Nm |

2400 |

||||||||

|

Spindle speed ranges |

rpm |

7.5-1000 |

||||||||

|

Spindle centre height |

mm |

315 |

400 |

515 |

||||||

|

Spindle motor power |

|

11kw(14.75 Horsepower),15kw(For special orders) |

||||||||

|

Tailstock |

||||||||||

|

Tailstock quill diameter |

mm |

φ100 |

||||||||

|

Tailstock quill travel |

mm |

240 |

||||||||

|

Tailstock quill taper |

No.6MT |

|||||||||

|

Feeds&Threads(metric screw*inch screw) |

||||||||||

|

Longitudinal feed |

mm/r |

64speeds 1/1 0.1-1.52 ; 16/1 1.6-24.3 |

||||||||

|

Cross feed |

|

1/2times of the longitudinal feed |

||||||||

|

Metric threads |

mm |

0.5-240 (52kinds) |

1-240( 50kinds) |

0.5-240(52kinds) |

||||||

|

Modular threads |

mm |

0.5-120( 53kinds) |

||||||||

|

Inch threads |

TPI |

28-1(34kindss) |

14-1(26kinds) |

28-1(34kinds) |

||||||

|

Diametral pitch threads |

DP |

28-1(24kinds) |

||||||||

|

Tool post |

||||||||||

|

Max.tool shank size |

mm |

30×30 |

||||||||

|

Top slide travel |

mm |

200 |

||||||||

|

Swivel angle of top slide |

|

±90° |

||||||||

|

Machine dimensions |

||||||||||

|

Machine dimensions (L x W x H) |

mm |

3190×1340×1830(1000) |

3190×1380×1830(1000) |

3190×1460×1830(1000) |

||||||

|

Machine weight |

C61xx |

kg |

3850/4150/4450/4950/5750/6450/7250/8250 |

4050/4350/4650/5150/6450/7150/7650/8650 |

4300/4600/4900/5400/6750/7250/7750/8250 |

|||||

|

C62xx |

4000/4300/4600/5100/5900/6600/7400/8400 |

4200/4500/4800/5300/6550/7250/7800/8800 |

4450/4750/5050/5550/6900/7400/7900/8400 |

|||||||

●3-Jaw chuck

●Chuck guard

●Tool post guard

●4-way tool post

●Steady rest(≥3000mm-Standard <3000mm-Option)

●Follow rest(≥3000mm-Standard <3000mm-Option)

●Standard toolkit

●4-Jaw chuck

●Rear splash guard

●Diameter of spindle boreφ130

●15kw spindle motor

●Center of tailstock

●Face plate

●Thread dial

●Taper-turning attachment

●DRO

●Anchor bolts

●Spindle center and center sleeve

●Adjustable pads

●Foot brake(1000mm~3000mm Available)

|

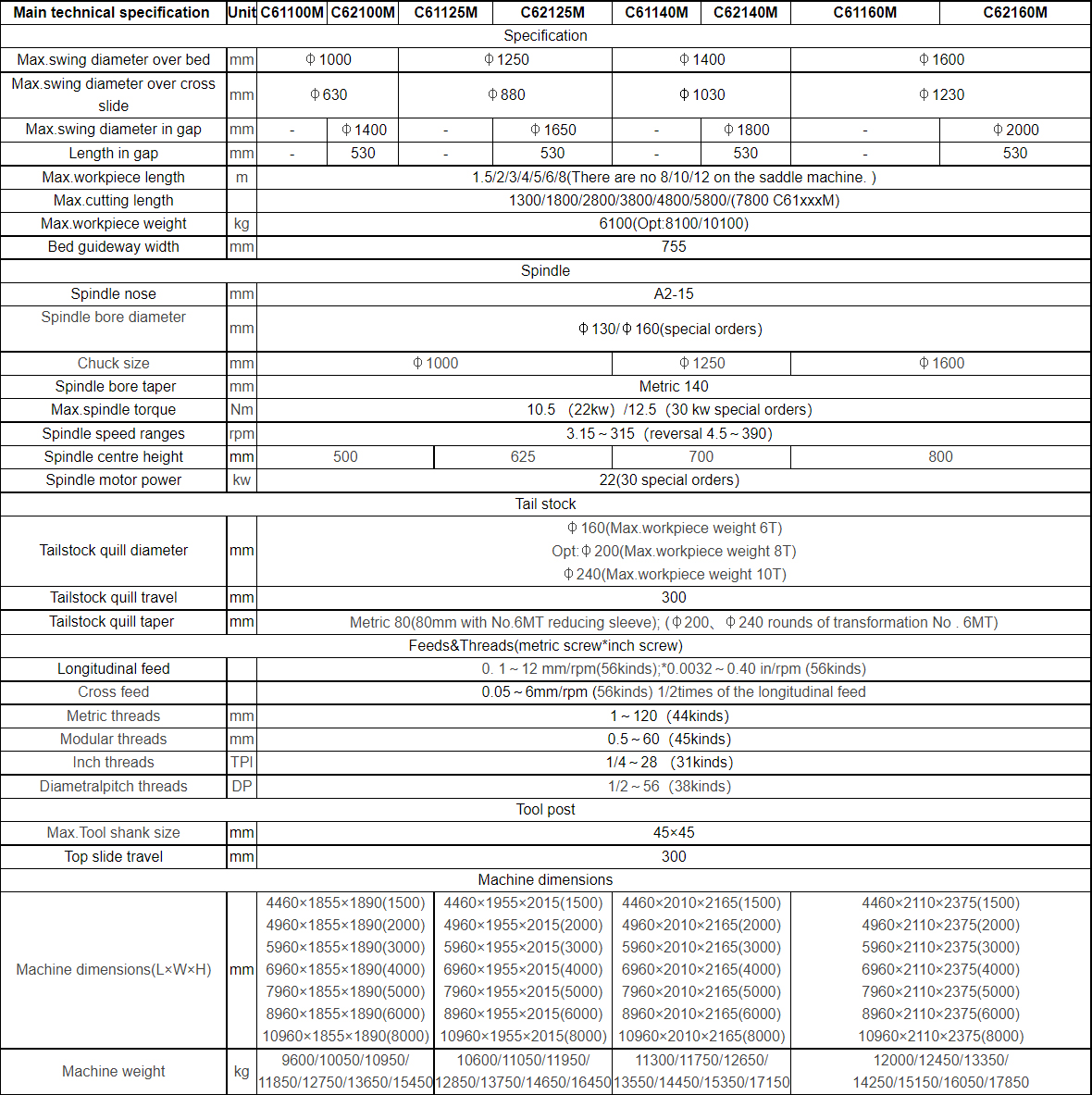

Main technical specification |

Unit |

C61100M |

C62100M |

C61125M |

C62125M |

C61140M |

C62140M |

C61160M |

C62160M |

|

|

Specification |

||||||||||

|

Max.swing diameter over bed |

mm |

φ1000 |

φ1250 |

φ1400 |

φ1600 |

|||||

|

Max.swing diameter over cross slide |

mm |

φ630 |

φ880 |

φ1030 |

φ1230 |

|||||

|

Max.swing diameter in gap |

mm |

- |

φ1400 |

- |

φ1650 |

- |

φ1800 |

- |

φ2000 |

|

|

Length in gap |

mm |

- |

530 |

- |

530 |

- |

530 |

- |

530 |

|

|

Max.workpiece length |

m |

1.5/2/3/4/5/6/8(There are no 8/10/12 on the saddle machine. ) |

||||||||

|

Max.cutting length |

|

1300/1800/2800/3800/4800/5800/(7800 C61xxxM) |

||||||||

|

Max.workpiece weight |

kg |

6100(Opt:8100/10100) |

||||||||

|

Bed guideway width |

mm |

755 |

||||||||

|

Spindle |

||||||||||

|

Spindle nose |

mm |

A2-15 |

||||||||

|

Spindle bore diameter

|

mm |

φ130/φ160(special orders) |

||||||||

|

Chuck size |

mm |

φ1000 |

φ1250 |

φ1600 |

||||||

|

Spindle bore taper |

mm |

Metric 140 |

||||||||

|

Max.spindle torque |

Nm |

10.5 (22kw)/12.5(30 kw special orders) |

||||||||

|

Spindle speed ranges |

rpm |

3.15~315(reversal 4.5~390) |

||||||||

|

Spindle centre height |

mm |

500 |

625 |

700 |

800 |

|||||

|

Spindle motor power |

kw |

22(30 special orders) |

||||||||

|

Tail stock |

||||||||||

|

Tailstock quill diameter |

mm |

φ160(Max.workpiece weight 6T) Opt:φ200(Max.workpiece weight 8T) φ240(Max.workpiece weight 10T) |

||||||||

|

Tailstock quill travel |

mm |

300 |

||||||||

|

Tailstock quill taper |

mm |

Metric 80(80mm with No.6MT reducing sleeve); (φ200、φ240 rounds of transformation No . 6MT) |

||||||||

|

Feeds&Threads(metric screw*inch screw) |

||||||||||

|

Longitudinal feed |

|

0. 1~12 mm/rpm(56kinds);*0.0032~0.40 in/rpm (56kinds) |

||||||||

|

Cross feed |

|

0.05~6mm/rpm (56kinds) 1/2times of the longitudinal feed |

||||||||

|

Metric threads |

mm |

1~120(44kinds) |

||||||||

|

Modular threads |

mm |

0.5~60(45kinds) |

||||||||

|

Inch threads |

TPI |

1/4~28 (31kinds) |

||||||||

|

Diametralpitch threads |

DP |

1/2~56(38kinds) |

||||||||

|

Tool post |

||||||||||

|

Max.Tool shank size |

mm |

45×45 |

||||||||

|

Top slide travel |

mm |

300 |

||||||||

|

Machine dimensions |

||||||||||

|

Machine dimensions(L×W×H) |

mm |

4460×1855×1890(1500) |

4460×1955×2015(1500) |

4460×2010×2165(1500) |

4460×2110×2375(1500) |

|||||

|

Machine weight |

kg |

9600/10050/10950/ |

10600/11050/11950/ |

11300/11750/12650/ |

12000/12450/13350/ 14250/15150/16050/17850 |

|||||

● 4-Jaw chuck

● Chuck guard

● Tool post guard

● 4-way tool post

● Steady rest(≥3000mm-Standard <3000mm-Option)

●Follow rest(≥3000mm-Standard<3000mm- Option)

● Center

● Spindle center sleeve

● Standard toolkit

● Rear splash guard

● Taper-turning attachment

● 30kw spindle motor

● DRO

● Thread dial

● Large-sized steady rest

● Roller device

● Heady duty tailstock

● Electric tailstockPersist with the policy of continual product improvement, we reserve the right to amend the specifications in this catalog without prior notice.