Welcome to Dalian Daxin Machinery Co., Ltd.

Toggle Navigation

|

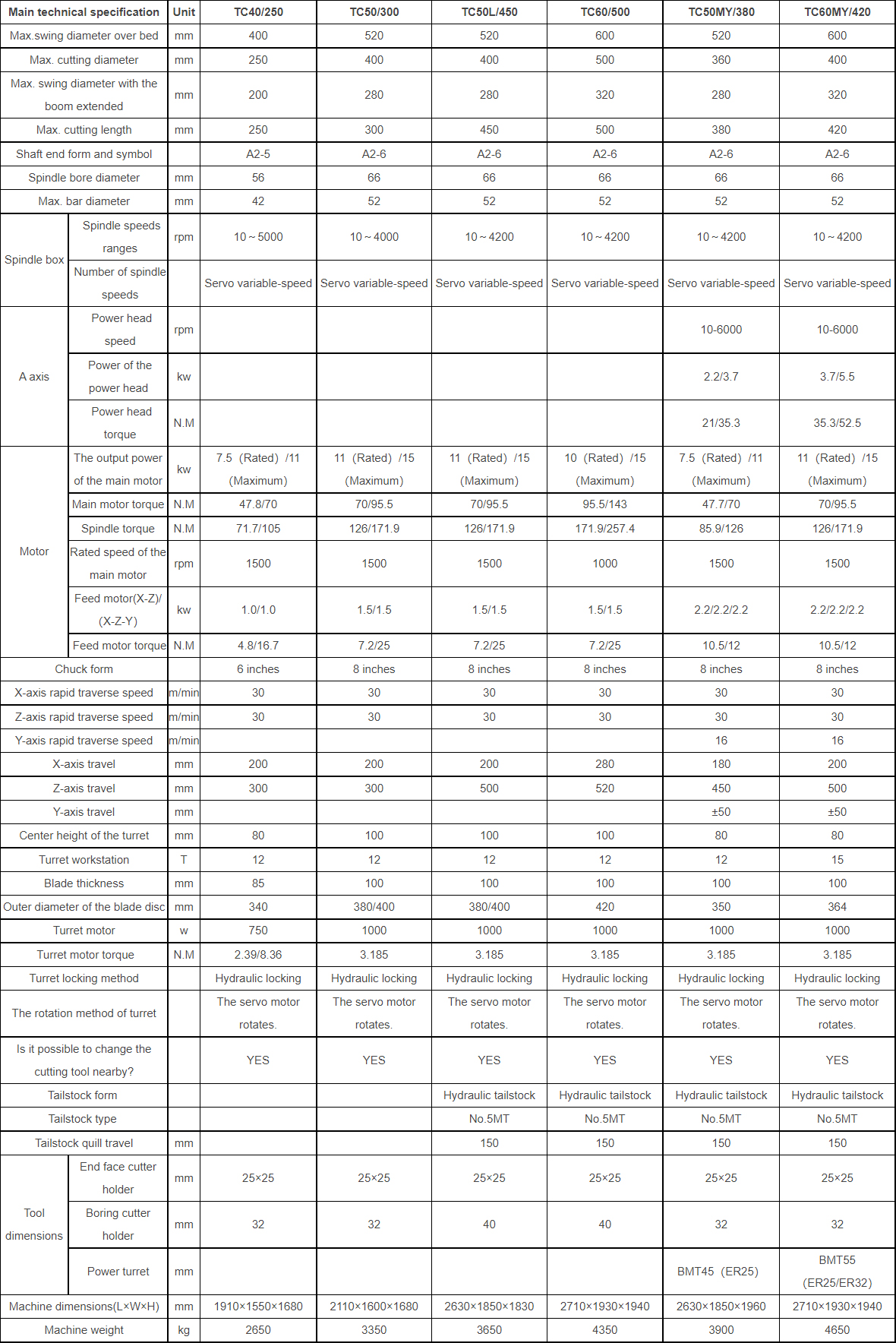

Main technical specification |

Unit |

TC40/250 |

TC50/300 |

TC50L/450 |

TC60/500 |

TC50MY/380 |

TC60MY/420 |

|

|

Max.swing diameter over bed |

mm |

400 |

520 |

520 |

600 |

520 |

600 |

|

|

Max. cutting diameter |

mm |

250 |

400 |

400 |

500 |

360 |

400 |

|

|

Max. swing diameter with the boom extended |

mm |

200 |

280 |

280 |

320 |

280 |

320 |

|

|

Max. cutting length |

mm |

250 |

300 |

450 |

500 |

380 |

420 |

|

|

Shaft end form and symbol |

|

A2-5 |

A2-6 |

A2-6 |

A2-6 |

A2-6 |

A2-6 |

|

|

Spindle bore diameter |

mm |

56 |

66 |

66 |

66 |

66 |

66 |

|

|

Max. bar diameter |

mm |

42 |

52 |

52 |

52 |

52 |

52 |

|

|

Spindle box |

Spindle speeds ranges |

rpm |

10~5000 |

10~4000 |

10~4200 |

10~4200 |

10~4200 |

10~4200 |

|

Number of spindle speeds |

|

Servo variable-speed |

Servo variable-speed |

Servo variable-speed |

Servo variable-speed |

Servo variable-speed |

Servo variable-speed |

|

|

A axis |

Power head speed |

rpm |

|

|

|

|

10-6000 |

10-6000 |

|

Power of the power head |

kw |

|

|

|

|

2.2/3.7 |

3.7/5.5 |

|

|

Power head torque |

N.M |

|

|

|

|

21/35.3 |

35.3/52.5 |

|

|

Motor |

The output power of the main motor |

kw |

7.5(Rated)/11(Maximum) |

11(Rated)/15(Maximum) |

11(Rated)/15(Maximum) |

10(Rated)/15(Maximum) |

7.5(Rated)/11(Maximum) |

11(Rated)/15(Maximum) |

|

Main motor torque |

N.M |

47.8/70 |

70/95.5 |

70/95.5 |

95.5/143 |

47.7/70 |

70/95.5 |

|

|

Spindle torque |

N.M |

71.7/105 |

126/171.9 |

126/171.9 |

171.9/257.4 |

85.9/126 |

126/171.9 |

|

|

Rated speed of the main motor |

rpm |

1500 |

1500 |

1500 |

1000 |

1500 |

1500 |

|

|

Feed motor(X-Z)/(X-Z-Y) |

kw |

1.0/1.0 |

1.5/1.5 |

1.5/1.5 |

1.5/1.5 |

2.2/2.2/2.2 |

2.2/2.2/2.2 |

|

|

Feed motor torque |

N.M |

4.8/16.7 |

7.2/25 |

7.2/25 |

7.2/25 |

10.5/12 |

10.5/12 |

|

|

Chuck form |

|

6 inches |

8 inches |

8 inches |

8 inches |

8 inches |

8 inches |

|

|

X-axis rapid traverse speed |

m/min |

30 |

30 |

30 |

30 |

30 |

30 |

|

|

Z-axis rapid traverse speed |

m/min |

30 |

30 |

30 |

30 |

30 |

30 |

|

|

Y-axis rapid traverse speed |

m/min |

|

|

|

|

16 |

16 |

|

|

X-axis travel |

mm |

200 |

200 |

200 |

280 |

180 |

200 |

|

|

Z-axis travel |

mm |

300 |

300 |

500 |

520 |

450 |

500 |

|

|

Y-axis travel |

mm |

|

|

|

|

±50 |

±50 |

|

|

Center height of the turret |

mm |

80 |

100 |

100 |

100 |

80 |

80 |

|

|

Turret workstation |

T |

12 |

12 |

12 |

12 |

12 |

15 |

|

|

Blade thickness |

mm |

85 |

100 |

100 |

100 |

100 |

100 |

|

|

Outer diameter of the blade disc |

mm |

340 |

380/400 |

380/400 |

420 |

350 |

364 |

|

|

Turret motor |

w |

750 |

1000 |

1000 |

1000 |

1000 |

1000 |

|

|

Turret motor torque |

N.M |

2.39/8.36 |

3.185 |

3.185 |

3.185 |

3.185 |

3.185 |

|

|

Turret locking method |

|

Hydraulic locking |

Hydraulic locking |

Hydraulic locking |

Hydraulic locking |

Hydraulic locking |

Hydraulic locking |

|

|

The rotation method of turret |

|

The servo motor rotates. |

The servo motor rotates. |

The servo motor rotates. |

The servo motor rotates. |

The servo motor rotates. |

The servo motor rotates. |

|

|

Is it possible to change the cutting tool nearby? |

|

YES |

YES |

YES |

YES |

YES |

YES |

|

|

Tailstock form |

|

|

|

Hydraulic tailstock |

Hydraulic tailstock |

Hydraulic tailstock |

Hydraulic tailstock |

|

|

Tailstock type |

|

|

|

No.5MT |

No.5MT |

No.5MT |

No.5MT |

|

|

Tailstock quill travel |

mm |

|

|

150 |

150 |

150 |

150 |

|

|

Tool dimensions |

End face cutter holder |

mm |

25×25 |

25×25 |

25×25 |

25×25 |

25×25 |

25×25 |

|

Boring cutter holder |

mm |

32 |

32 |

40 |

40 |

32 |

32 |

|

|

Power turret |

mm |

|

|

|

|

BMT45(ER25) |

BMT55(ER25/ER32) |

|

|

Machine dimensions(L×W×H) |

mm |

1910×1550×1680 |

2110×1600×1680 |

2630×1850×1830 |

2710×1930×1940 |

2630×1850×1960 |

2710×1930×1940 |

|

|

Machine weight |

kg |

2650 |

3350 |

3650 |

4350 |

3900 |

4650 |

|

● Mitsubishi M80LA

● Linear roller guideway

● Through-hole hydraulic chuck and cylinder

● Hydraulic tailstock(DT-30 Hydraulic tailstock )

● RH-mounted chain-type chip conveyor

● Heat exchanger

● Alarm stack light

● Semi-closed-loop measuring device

● Standard toolkit

● Siemens CNC system

● Guangzhou CNC system

● Tool checking instrument

● Workpiece detector

● Oil mist collector

● Automatic material feeding system