Welcome to Dalian Daxin Machinery Co., Ltd.

Toggle Navigation

|

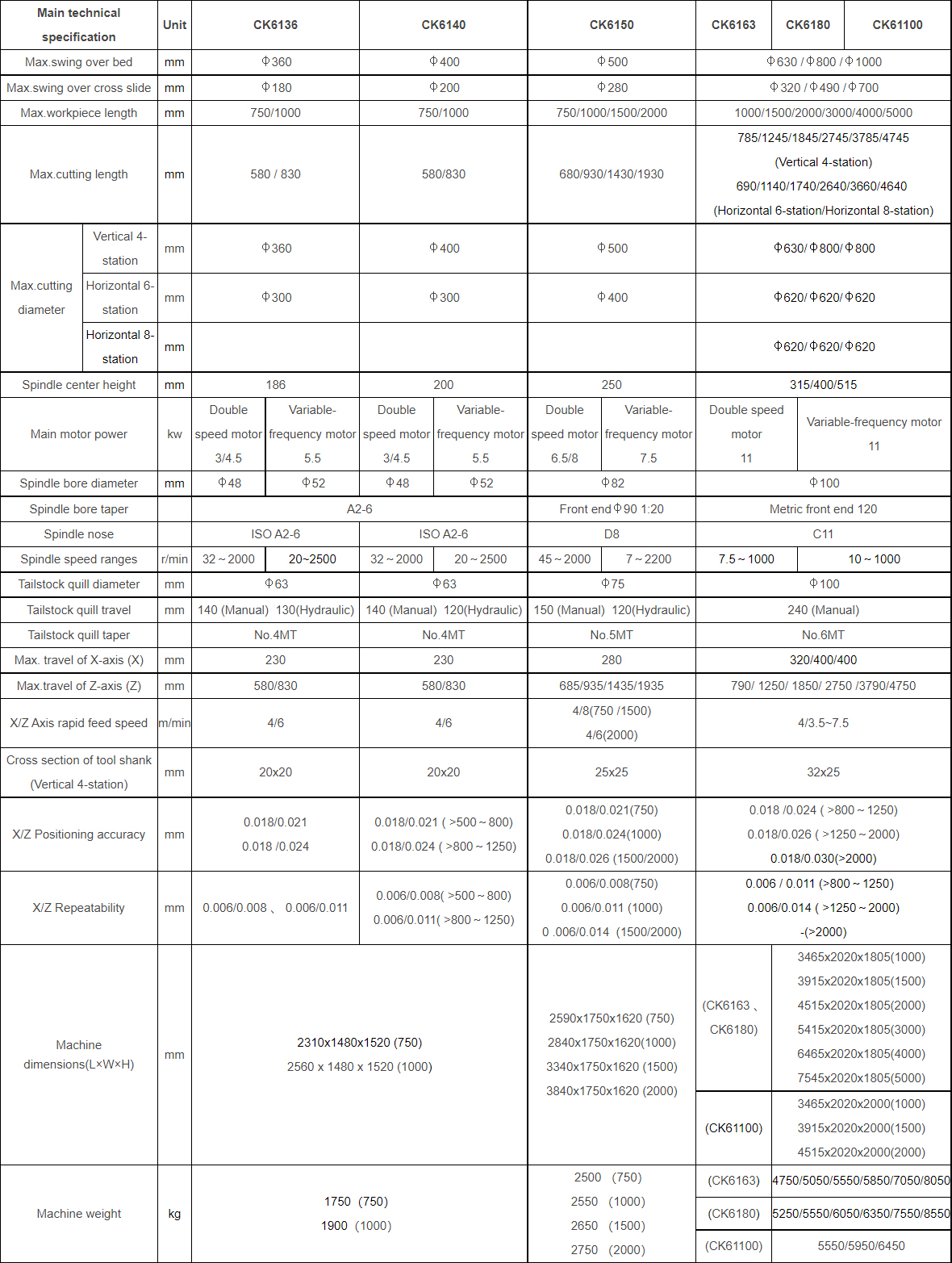

Main technical specification |

Unit |

CK6136 |

CK6140 |

CK6150 |

CK6163 |

CK6180 |

CK61100 |

|||||

|

Max.swing over bed |

mm |

φ360 |

φ400 |

φ500 |

φ630 /φ800 /φ1000 |

|||||||

|

Max.swing over cross slide |

mm |

φ180 |

φ200 |

φ280 |

φ320 /φ490 /φ700 |

|||||||

|

Max.workpiece length |

mm |

750/1000 |

750/1000 |

750/1000/1500/2000 |

1000/1500/2000/3000/4000/5000 |

|||||||

|

Max.cutting length |

mm |

580 / 830 |

580/830 |

680/930/1430/1930 |

785/1245/1845/2745/3785/4745

(Vertical 4-station) (Horizontal 6-station/Horizontal 8-station) |

|||||||

|

Max.cutting diameter |

Vertical 4-station |

mm |

φ360 |

φ400 |

φ500 |

φ630/φ800/φ800 |

||||||

|

Horizontal 6-station |

mm |

φ300 |

φ300 |

φ400 |

φ620/φ620/φ620 |

|||||||

|

Horizontal 8-station |

mm |

|

|

|

φ620/φ620/φ620 |

|||||||

|

Spindle center height |

mm |

186 |

200 |

250 |

315/400/515 |

|||||||

|

Main motor power |

kw |

Double speed motor |

Variable-frequency motor |

Double speed motor |

Variable-frequency motor |

Double speed motor |

Variable-frequency motor |

Double speed motor |

Variable-frequency motor |

|||

|

Spindle bore diameter |

mm |

φ48 |

φ52 |

φ48 |

φ52 |

φ82 |

φ100 |

|||||

|

Spindle bore taper |

|

A2-6 |

Front endφ90 1:20 |

Metric front end 120 |

||||||||

|

Spindle nose |

|

ISO A2-6 |

ISO A2-6 |

D8 |

C11 |

|||||||

|

Spindle speed ranges |

r/min |

32~2000 |

20~2500 |

32~2000 |

20~2500 |

45~2000 |

7~2200 |

7.5~1000 |

10~1000 |

|||

| Tailstock quill diameter |

mm |

φ63 |

φ63 |

φ75 |

φ100 |

|||||||

|

Tailstock quill travel |

mm |

140 (Manual) 130(Hydraulic) |

140 (Manual) 120(Hydraulic) |

150 (Manual) 120(Hydraulic) |

240 (Manual) |

|||||||

|

Tailstock quill taper |

|

No.4MT |

No.4MT |

No.5MT |

No.6MT |

|||||||

|

Max. travel of X-axis (X) |

mm |

230 |

230 |

280 |

320/400/400 |

|||||||

|

Max.travel of Z-axis (Z) |

mm |

580/830 |

580/830 |

685/935/1435/1935 |

790/ 1250/ 1850/ 2750 /3790/4750 |

|||||||

|

X/Z Axis rapid feed speed |

m/min |

4/6 |

4/6 |

4/8(750 /1500) 4/6(2000) |

4/3.5~7.5 |

|||||||

|

Cross section of tool shank (Vertical 4-station) |

mm |

20x20 |

20x20 |

25x25 |

32x25 |

|||||||

|

X/Z Positioning accuracy |

mm |

0.018/0.021 |

0.018/0.021 ( >500~800) |

0.018/0.021(750) 0.018/0.026 (1500/2000) |

0.018 /0.024 ( >800~1250) |

|||||||

|

X/Z Repeatability |

mm |

0.006/0.008 、 0.006/0.011 |

0.006/0.008( >500~800) |

0.006/0.008(750) |

0.006 / 0.011 (>800~1250) -(>2000) |

|||||||

|

Machine dimensions(L×W×H) |

mm |

2310x1480x1520 (750) |

2590x1750x1620 (750) 2840x1750x1620(1000) 3340x1750x1620 (1500) 3840x1750x1620 (2000) |

(CK6163 、 CK6180) |

3465x2020x1805(1000) |

|||||||

|

(CK61100) |

3465x2020x2000(1000) 3915x2020x2000(1500) 4515x2020x2000(2000) |

|||||||||||

|

Machine weight |

kg |

1750(750) |

2500 (750) |

(CK6163) |

4750/5050/5550/5850/7050/8050 |

|||||||

|

(CK6180) |

5250/5550/6050/6350/7550/8550 |

|||||||||||

|

(CK61100) |

5550/5950/6450 |

|||||||||||

● FANUC CNC system

● 3-Jaw manual chuck

● Vertical 4-station

● Workpiece cooling system

● Automatic lubricating system

● Manual tailstock

● Center used on the tailstock

● Standard toolkit

● Chip receiving box

● Siemens CNC system

● Guangzhou CNC system

● 4-Jaw manual chuck

● 6 Horizontal tool post

● 8 Horizontal tool post

● Hydraulic chuck

● Hydraulic tailstock

● Steady rest

● Tool setting instrument

Persist with the policy of continual product improvement, we reserve the right to amend the specifications in this catalog without prior notice.

|

Main technical specification |

Unit |

CK61100P |

CK61125P |

|

Max.swing over bed |

mm |

φ1000 /φ1250 |

|

|

Max.swing over cross slide |

mm |

φ630 /φ880 |

|

|

Max.workpiece length |

mm |

1500/2000/3000/4000/5000/6000 |

|

|

Max.cutting length |

mm |

1400/1900/2900/3900/4900/5900 |

|

|

Max.cutting diameter |

mm |

φ1000/φ1250( Vertical 4-station ) |

|

|

Spindle center height |

mm |

500 / 625 |

|

|

Main motor power (Servo motor) |

kw |

22/26(FANUC) |

|

|

Spindle bore diameter |

mm |

φ130 |

|

|

Spindle bore taper |

|

Front end φ140mm 1:20 |

|

|

Spindle nose |

|

A2-15 |

|

|

Spindle speed ranges (Electric three-speed automatic shifting, with variable speed within each gear) |

r/min |

Install chucks with a diameter of 800 or less, speed limit of 2 to 500. |

|

|

Install diameter 1000 chuck, speed limit of 2 to 315 |

|||

|

Install a 1250mm chuck with a speed limit of 2 to 280 |

|||

|

Tailstock quill diameter |

mm |

φ200 |

|

|

Tailstock quill travel |

mm |

300 |

|

|

Tailstock quill taper |

|

No.6MT |

|

|

Max.travel of X-axis |

mm |

520 / 640 |

|

|

Max.travel of Z-axis |

mm |

1500/2000/3000/4000/5000/6000 |

|

|

X/Z axis rapid feed speed |

m/min |

6/8 |

|

|

Cross section of tool shank(Vertical 4-station) |

mm |

40x40 |

|

|

X/ Z Positioning accuracy |

mm |

0.021/ 0.026( >1250~2000 )、 0.021/ 0.030 (>2000 ) |

|

|

X/ Z Repeatability |

mm |

0.008/ 0.014( >1250~2000 )、 -( >2000) |

|

|

Machine dimensions(L X W X H) |

mm |

6330x2300x2200(1500) |

6330 x2520x2300(1500) |

|

Machine weight |

kg |

13450 /13950 /14950 /15950 /16950 /17950 |

14450 /14950 /15950 /16950 /17950 /18950 |

●FANUC CNC system

● 4-Jaw Chuck

● Vertical 4-stationl tool post

● The bed saddle drags the tailstock

● Chain-Type chip conveyor

● Standard tools

● Heat exchanger for electrical cabinet

● Siemens CNC system

● Guangzhou CNC system

● Horizontal 8-station tool post

● Steady rest

● Follower rest

● Thermal stable unit in electrical cabinet

● CE Certified electrical component