Welcome to Dalian Daxin Machinery Co., Ltd.

Toggle Navigation

|

Technical Data |

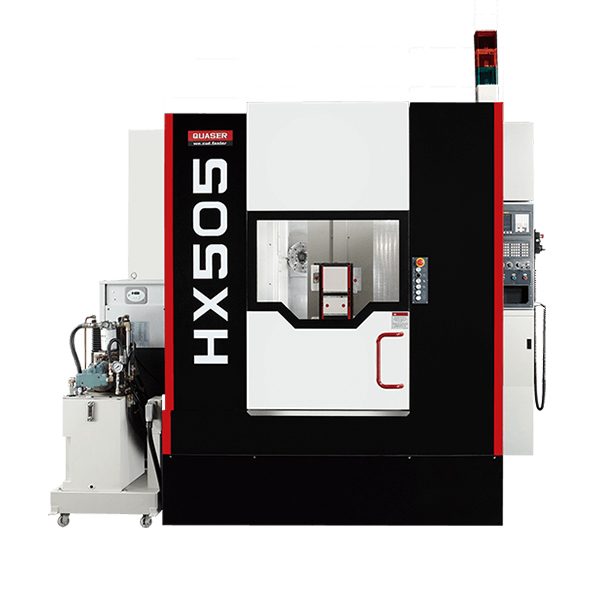

HX504 | HX505 |

|

Work Range |

||

|

Workbench size |

500 mm |

500 mm |

|

Maximum workpiece turn diameter |

Ø762 mm |

Ø800 mm |

|

Maximum workpiece height |

900 mm |

900 mm |

|

X-axis travel |

762 mm |

762 mm |

|

Y-axis travel |

640 mm |

640 mm |

|

Z-axis travel |

810 mm |

800 mm |

|

B-axis minimum division (Degree) |

1/0.001 |

1 |

|

Table load |

500 kg |

500 kg |

|

Work change |

||

|

The number of workbenches |

2 |

2 |

|

Workbench exchange method |

Arm type |

Arm type |

|

Main Spindle |

||

|

Spindle type |

40 taper |

50 taper |

|

Maximum spindle speed |

8K ~ 15K |

6K ~ 10K |

|

Automatic tool changing system |

||

|

Tool magazine capacity |

60 (std.) |

40 (std.) |

|

Maximum blade diameter |

76.2 mm |

110 mm |

|

There is no maximum diameter of adjacent knives |

150 mm |

220 mm |

| Maximum tool length |

450 mm |

400 mm |

|

Technical Data |

HX504 | HX505 |

|

Work Range |

||

|

Workbench size |

500 mm |

500 mm |

|

Maximum workpiece turn diameter |

Ø762 mm |

Ø800 mm |

|

Maximum workpiece height |

900 mm |

900 mm |

|

X-axis travel |

762 mm |

762 mm |

|

Y-axis travel |

640 mm |

640 mm |

|

Z-axis travel |

810 mm |

800 mm |

|

B-axis minimum division (Degree) |

1/0.001 |

1 |

|

Table load |

500 kg |

500 kg |

|

Work change |

||

|

The number of workbenches |

2 |

2 |

|

Workbench exchange method |

Arm type |

Arm type |

|

Main Spindle |

||

|

Spindle type |

40 taper |

50 taper |

|

Maximum spindle speed |

8K ~ 15K |

6K ~ 10K |

|

Automatic tool changing system |

||

|

Tool magazine capacity |

60 (std.) |

40 (std.) |

|

Maximum blade diameter |

76.2 mm |

110 mm |

|

There is no maximum diameter of adjacent knives |

150 mm |

220 mm |

| Maximum tool length |

450 mm |

400 mm |